Insulating Sticks and Accessories

Insulating sticks are protective devices designed and manufactured to prevent contact with live conductive parts or which become live accidentally and to provide the minimum approach distance towards live parts during maneuvers in indoor or outdoor electrical installations. If in the case of low voltage installations there isn't a minimum approach distance and only the direct contact with live elements is forbidden, in medium and high voltage installations the minimum approach distance is currently established by electricity distribution and transmission companies (provided by internal regulations), and varies depending on the nominal voltage of the installation and the type of installation. The nominal voltage of the installation represents the operating voltage of the insulating sticks (Un).Insulating sticks consist of insulating tubes made of fiberglass-reinforced resin, provided at the working end with:

Insulating sticks are protective devices designed and manufactured to prevent contact with live conductive parts or which become live accidentally and to provide the minimum approach distance towards live parts during maneuvers in indoor or outdoor electrical installations. If in the case of low voltage installations there isn't a minimum approach distance and only the direct contact with live elements is forbidden, in medium and high voltage installations the minimum approach distance is currently established by electricity distribution and transmission companies (provided by internal regulations), and varies depending on the nominal voltage of the installation and the type of installation. The nominal voltage of the installation represents the operating voltage of the insulating sticks (Un).Insulating sticks consist of insulating tubes made of fiberglass-reinforced resin, provided at the working end with:

- parts that allow the operation of some of the installation elements (typically hook-shaped);

- systems that allow the attachment of other protection devices.

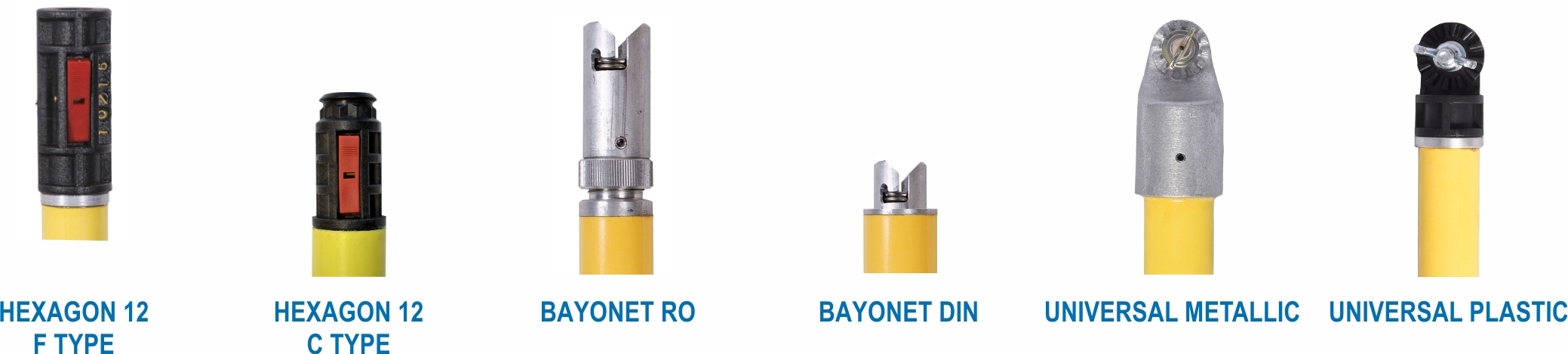

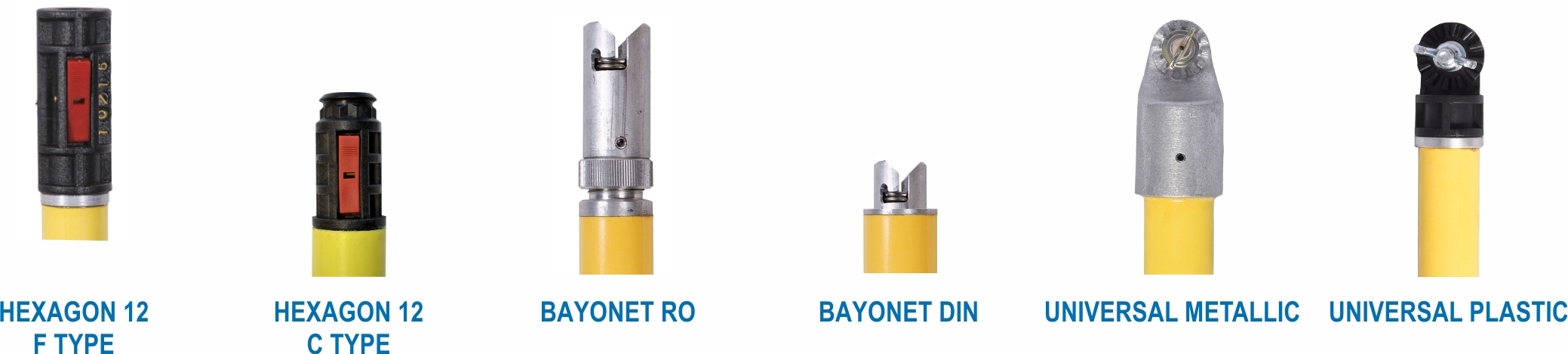

The most common coupling systems found on the Romanian market are:

- “Hexagon 12” F type seat system (typically made of plastic and found mainly in telescopic sticks),

- “Hexagon 12 & thread M10” C type seat system (typically made of plastic and metallic elements and found mainly in telescopic sticks),

and

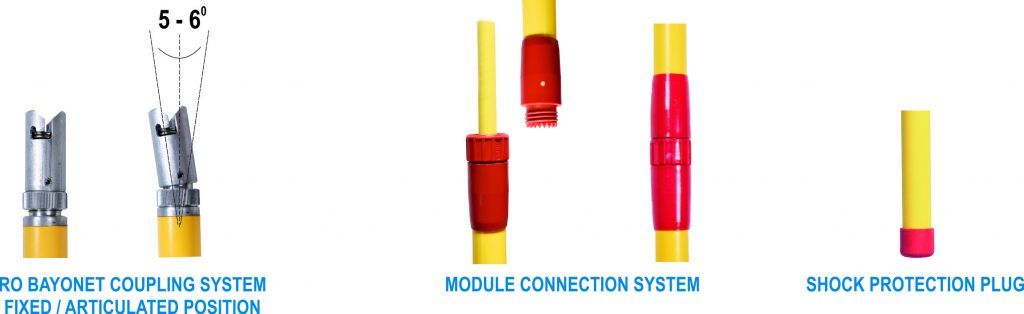

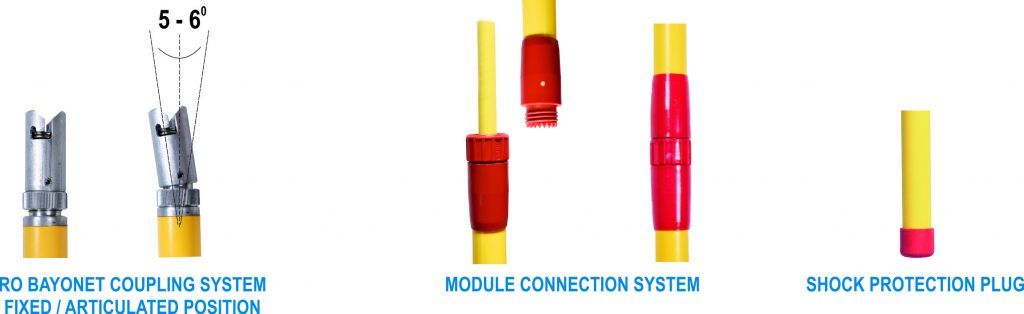

- “RO bayonet” seat system (made of metallic items, found mainly in modular sticks used for the application of short-circuiting devices provided with tightening clamps on the busbar by means of a screw).

Apart from these two systems, sticks can be provided, upon the client’s express demand, with:

- “DIN bayonet” seated coupling system (made of metallic items),

- “Universal” coupling system (rose-shaped, made of metal or plastic).

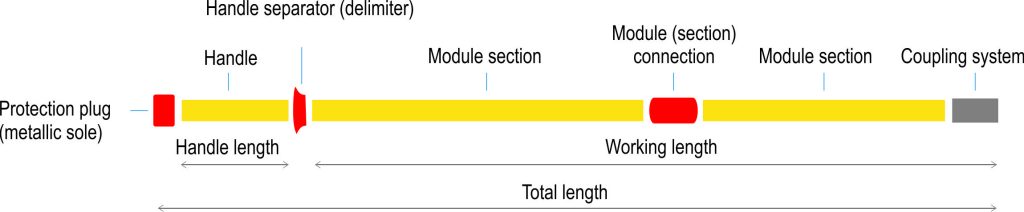

All insulating stick are provided with a handle separator (limiter) to indicate that during the use of the stick, the operator’s hand must be placed exclusively on the handle area. This limiter typically consists of a plastic ring or, in special cases, of a label.

The vast majority of sticks are provided in the end area of the handle with a shock protection plug.

Sticks that must be handled / extended vertically, without being lifted from the ground, are provided with a metallic sole to improve stability during operation, the sole being pushed on the ground by the operator’s foot.

Upon the client’s express demand, particular stick types can be provided with extension pieces made of fiberglass-reinforced resin tubes to increase the stick handle length.

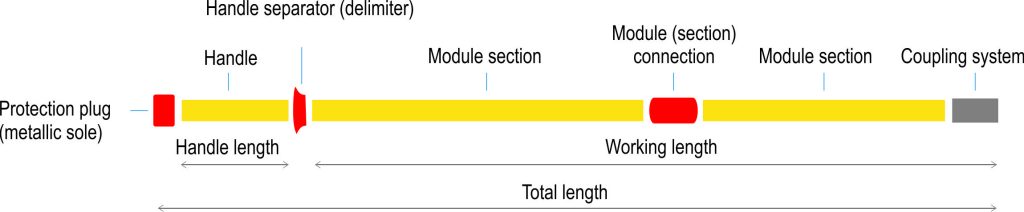

Sticks have the following dimensional characteristics:

- total length of the stick - measured between the two extremities, in the circumstances that all stick modules are interconnected or all sections of the telescopic stick are extended to the maximum;

- working length of the stick - measured by the extremity that includes the coupling system or the handling piece (work head) to the handle separator (as above). This working length must be higher than or equal to the approach distance specified in the regulations in force.

- handle length - measured from the handle separator ring to the other extremity of the stick (insulating plug), practically the length of the area touchable by the operator’s hands;

- transport length - measured in the circumstances that the stick modules are disconnected or the sections of the telescopic stick are folded into transport position;

- module/section diameter - outer diameters of tubes included in the stick;

- weight - stick weight without transport casing.

Insulating sticks are manufactured in multiple constructive versions:

Insulating sticks are manufactured in multiple constructive versions:

- modular, multipurpose (from multiple connecting elements (modules);

- telescopic, multipurpose (with multiple extensible sections);special design (engineered for a particular application).

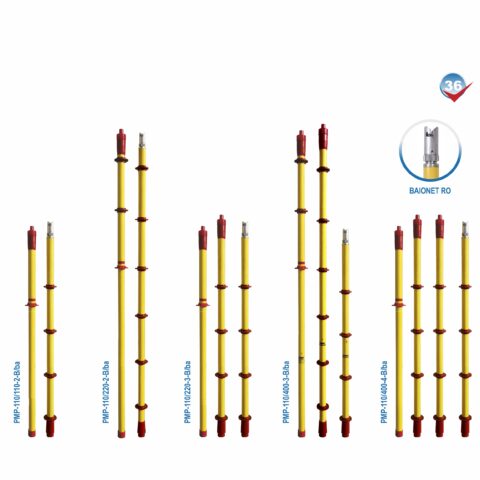

Multipurpose modular insulating sticks (PMU or PMP) consist of one or more elements (modules) that can be assembled mechanically to obtain complete equipment and are provided with “RO bayonet” seat coupling system which allows the attachment of other protection devices, adaptors or accessories (optionally, they can be provided with other coupling systems, according to the client’s request).“RO bayonet” coupling system can be adjusted into two positions:

- “fixed” when the adjustment nut blocks the coupling system on the same axis with the stick axis, and

“articulated” when the fixing nut is loosened and allows the coupling system to be arranged in a position inclined in any direction, by maximum 6° from the stick axis.

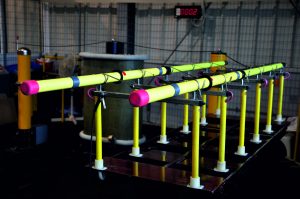

The connection system between the stick modules is of bayonet type and typically consists of plastic parts, with good mechanical properties and shock resistance. Modular PMU sticks can be used in indoor or outdoor power installations only in dry conditions.Modular PMP sticks can be used in indoor or outdoor power installations in dry and wet conditions.

Multipurpose telescopic insulating sticks (PTU) are manufactured from two or more tubular items (of various diameters) which can be extended or folded in locked position and are provided with “hexagon 12” coupling system which allows the coupling of other protection devices, adapters or accessories (optionally, they can be provided with other coupling systems, depending on the client’s requests). The stick is fastened in its operating position by the extension of sections (from the smallest diameter to the largest diameter) and locking of their position by means of spring-loaded push buttons. The attachment of the voltage detector or of a different equipment in the hexagonal seat coupling system is ratcheted in position, and they are detached by the push of the coupling system lever button.In order to prevent damage or locking of push button drives, on long telescopic sticks the button area is covered with a semi-transparent elastic sleeve, thus preventing the penetration of dust, sand or water in this area. These elastic sleeves provide the sticks with better resistance to shocks generated by the stick falling on the ground. PTU telescopic sticks can be used in indoor or outdoor electrical installations in dry conditions.

Multipurpose telescopic insulating sticks (PTU) are manufactured from two or more tubular items (of various diameters) which can be extended or folded in locked position and are provided with “hexagon 12” coupling system which allows the coupling of other protection devices, adapters or accessories (optionally, they can be provided with other coupling systems, depending on the client’s requests). The stick is fastened in its operating position by the extension of sections (from the smallest diameter to the largest diameter) and locking of their position by means of spring-loaded push buttons. The attachment of the voltage detector or of a different equipment in the hexagonal seat coupling system is ratcheted in position, and they are detached by the push of the coupling system lever button.In order to prevent damage or locking of push button drives, on long telescopic sticks the button area is covered with a semi-transparent elastic sleeve, thus preventing the penetration of dust, sand or water in this area. These elastic sleeves provide the sticks with better resistance to shocks generated by the stick falling on the ground. PTU telescopic sticks can be used in indoor or outdoor electrical installations in dry conditions.

Specialized insulating sticks are sticks designed to perform in safety conditions a single operation, being provided at the working end with various hook-shaped parts (usually metallic). This class includes:

Specialized insulating sticks are sticks designed to perform in safety conditions a single operation, being provided at the working end with various hook-shaped parts (usually metallic). This class includes:

- sticks for the handling of disconnectors (PSU type),

- sticks for the handling of cables (PCU type),

- sticks for the operation of electrical equipment (PAE type),

- sticks for the rescue of injured persons (rescue sticks with hook).

All these specialized sticks can be used in indoor or outdoor electrical installations, in dry conditions. Depending on the field of use, insulating sticks are manufactured according to the provisions of SR EN 61230; SR EN 61235; SR EN 50508. In order to allow the use of sticks for various purposes, they can be accompanied by a series of other equipment, adapters and accessories. Adapters are devices that connect the coupling system at the end of sticks and other equipment used for works / operations on medium and high voltage outdoor electrical installations. Accessories are devices used in conjunction with insulating sticks to perform various works / operations in power installations.The main applications that require the use of insulating sticks are the following:

- assembly and disassembly of phase clamps of short-circuiting switches;

- assembly and disassembly of electrically insulating plates, sheaths or electrically insulating caps;

- assembly and disassembly of hooks / anchoring devices for work at height; handling of switches;

- handling of live cables;

- cut-off of electrical connections in case of emergency; inspection of presence/absence of voltage with a voltage detector;

- inspection of phase load (current measurement) using tong test ammeters;

- inspection of the phase correspondence using homopolar phase indicator; assembly of fault indicators on live overhead lines;

- detachment of a person subject to electric shock from the live electrical installation of contact and rescue outside the hazard area to provide first aid;

- discharge of capacitive loads using an appropriate set of fuses;

- elevation of annunciators assembled on cables;

- removal of various objects fallen on live electrical leads;

- deforestation in the proximity of live power installations;

- cleaning of conductors, bars or insulators of live electrical installations, using various types of brushes or other devices;

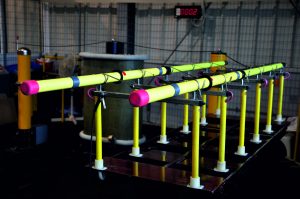

Insulating sticks must be used in the installations and in their intended purposes, specified in the operating instructions of sticks. Insulating sticks are protective devices that require periodical dielectric inspection to make sure that their insulating properties are maintained. The voltage of their inspection is called test voltage, with a value regulated by standards according to the operating voltage. Periodical checks must be provided in special conditions, in Laboratories certified by RENAR, the Romanian Accreditation Association, for such tests.

Note: Romind T&G includes a high-voltage test laboratory accredited by RENAR.

Insulating sticks are delivered packed in waterproof bags.

Insulating sticks are protective devices designed and manufactured to prevent contact with live conductive parts or which become live accidentally and to provide the minimum approach distance towards live parts during maneuvers in indoor or outdoor electrical installations. If in the case of low voltage installations there isn't a minimum approach distance and only the direct contact with live elements is forbidden, in medium and high voltage installations the minimum approach distance is currently established by electricity distribution and transmission companies (provided by internal regulations), and varies depending on the nominal voltage of the installation and the type of installation. The nominal voltage of the installation represents the operating voltage of the insulating sticks (Un).Insulating sticks consist of insulating tubes made of fiberglass-reinforced resin, provided at the working end with:

Insulating sticks are protective devices designed and manufactured to prevent contact with live conductive parts or which become live accidentally and to provide the minimum approach distance towards live parts during maneuvers in indoor or outdoor electrical installations. If in the case of low voltage installations there isn't a minimum approach distance and only the direct contact with live elements is forbidden, in medium and high voltage installations the minimum approach distance is currently established by electricity distribution and transmission companies (provided by internal regulations), and varies depending on the nominal voltage of the installation and the type of installation. The nominal voltage of the installation represents the operating voltage of the insulating sticks (Un).Insulating sticks consist of insulating tubes made of fiberglass-reinforced resin, provided at the working end with:

Insulating sticks are manufactured in multiple constructive versions:

Insulating sticks are manufactured in multiple constructive versions:

Multipurpose telescopic insulating sticks (PTU) are manufactured from two or more tubular items (of various diameters) which can be extended or folded in locked position and are provided with “hexagon 12” coupling system which allows the coupling of other protection devices, adapters or accessories (optionally, they can be provided with other coupling systems, depending on the client’s requests). The stick is fastened in its operating position by the extension of sections (from the smallest diameter to the largest diameter) and locking of their position by means of spring-loaded push buttons. The attachment of the voltage detector or of a different equipment in the hexagonal seat coupling system is ratcheted in position, and they are detached by the push of the coupling system lever button.In order to prevent damage or locking of push button drives, on long telescopic sticks the button area is covered with a semi-transparent elastic sleeve, thus preventing the penetration of dust, sand or water in this area. These elastic sleeves provide the sticks with better resistance to shocks generated by the stick falling on the ground. PTU telescopic sticks can be used in indoor or outdoor electrical installations in dry conditions.

Multipurpose telescopic insulating sticks (PTU) are manufactured from two or more tubular items (of various diameters) which can be extended or folded in locked position and are provided with “hexagon 12” coupling system which allows the coupling of other protection devices, adapters or accessories (optionally, they can be provided with other coupling systems, depending on the client’s requests). The stick is fastened in its operating position by the extension of sections (from the smallest diameter to the largest diameter) and locking of their position by means of spring-loaded push buttons. The attachment of the voltage detector or of a different equipment in the hexagonal seat coupling system is ratcheted in position, and they are detached by the push of the coupling system lever button.In order to prevent damage or locking of push button drives, on long telescopic sticks the button area is covered with a semi-transparent elastic sleeve, thus preventing the penetration of dust, sand or water in this area. These elastic sleeves provide the sticks with better resistance to shocks generated by the stick falling on the ground. PTU telescopic sticks can be used in indoor or outdoor electrical installations in dry conditions.

Specialized insulating sticks are sticks designed to perform in safety conditions a single operation, being provided at the working end with various hook-shaped parts (usually metallic). This class includes:

Specialized insulating sticks are sticks designed to perform in safety conditions a single operation, being provided at the working end with various hook-shaped parts (usually metallic). This class includes: