Mobile earthing and short-circuiting devices (currently referred to as “short-circuiting devices”) represent safety equipment used for temporary earthing and short-circuiting of conductors of a power installation.

The use of short-circuiting devices represents the main preventive protection measure for professional operators against an accidental commissioning or possible voltage return during repair operations in the working area.

The installation of short-circuiting devices must be performed by two professional operators, in the following sequence of operations:

- Earthing of the short-circuiting device by the fastening of the earthing clamp or of the crimped lug of the earthing cable to the artificial / natural earth grounding of the power installation or to the mobile earthing rod, previously buried;

- Checking the absence of voltage on conductors to be earthed / short-circuited, using a voltage detector;

- Installation of the phase clamps (CLF) of the short-circuiting device, which allow a good connection between the phase conductor and the earth.

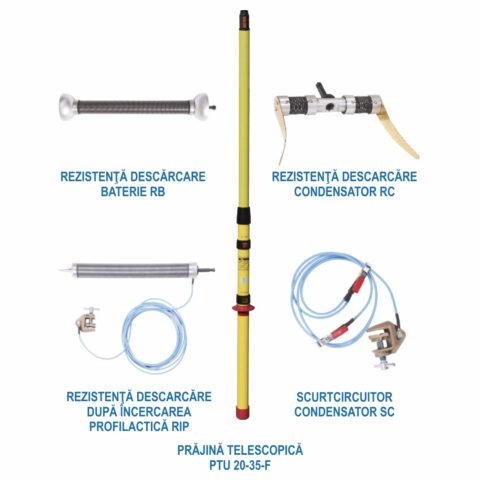

Depending on the type of the short-circuiting device and the voltage of the power installation where the short-circuiting device is applied, the installation of the phase clamps on the conductors must be performed using insulating sticks / poles / handles specially designed for this operation.

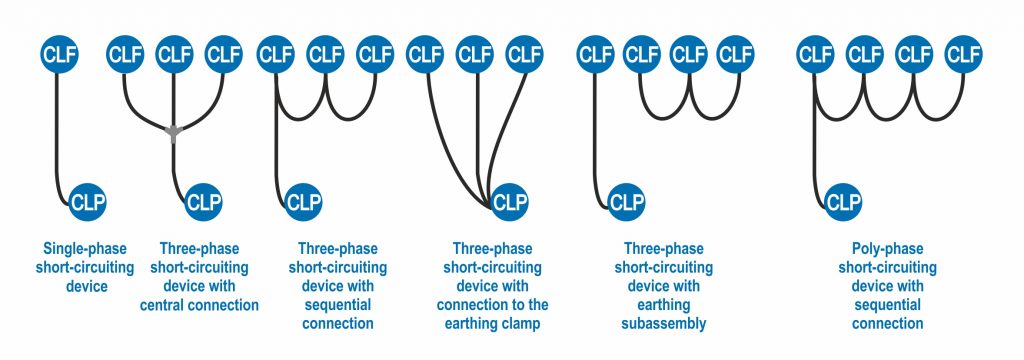

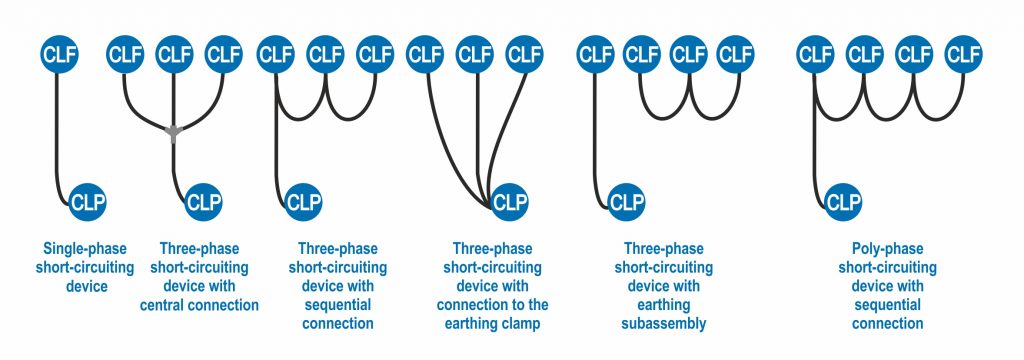

Short-circuiting devices are made in accordance with the provisions of SR EN 61230 standard, in various constructive configurations: single-phase, three-phase or poly-phase and can be installed both in indoor and outdoor power installations. Short-circuiting and earthing cables will be connected in various configurations, according to the needs.

Mobile earthing and short-circuiting devices (currently referred to as “short-circuiting devices”) represent safety equipment used for temporary earthing and short-circuiting of conductors of a power installation.

The use of short-circuiting devices represents the main preventive protection measure for professional operators against an accidental commissioning or possible voltage return during repair operations in the working area.

The installation of short-circuiting devices must be performed by two professional operators, in the following sequence of operations:

- Earthing of the short-circuiting device by the fastening of the earthing clamp or of the crimped lug of the earthing cable to the artificial / natural earth grounding of the power installation or to the mobile earthing rod, previously buried;

- Checking the absence of voltage on conductors to be earthed / short-circuited, using a voltage detector;

- Installation of the phase clamps (CLF) of the short-circuiting device, which allow a good connection between the phase conductor and the earth.

Depending on the type of the short-circuiting device and the voltage of the power installation where the short-circuiting device is applied, the installation of the phase clamps on the conductors must be performed using insulating sticks / poles / handles specially designed for this operation.

Short-circuiting devices are made in accordance with the provisions of SR EN 61230 standard, in various constructive configurations: single-phase, three-phase or poly-phase and can be installed both in indoor and outdoor power installations. Short-circuiting and earthing cables will be connected in various configurations, according to the needs.

The central junction of the three-phase short-circuiting devices can be constructed in two design variants: with a central connector insulated with heat shrink tube or with a connecting block covered with insulating housing, that allows inspection of the junction.

The central junction of the three-phase short-circuiting devices can be constructed in two design variants: with a central connector insulated with heat shrink tube or with a connecting block covered with insulating housing, that allows inspection of the junction.

The short-circuiting and earthing cables of the short-circuiting device are manufactured from highly flexible multi-core copper wire, class VI according to SR EN 60228, protected with a transparent insulating layer, directly extruded on the multi-core wire, according to SR EN 61138.

Phase clamps (CLF) and earthing clamps (CLP) are designed and manufactured in a wide range of constructive shapes so that they can be applied on the various shapes of conductors of the low, medium and high voltage installations and to provide the mechanical strength required for the successful handling of an incident determined by the accidental occurrence of voltage in the power installation. Even if it may seem less important, the correct selection of phase and earthing clamps assures improved ergonomic conditions and, at the same time, complete electrical safety.

Phase and earthing clamps are fastened on the installation's conductors or on the earth bars by various methods:

- Screw fastening (where the conductor is firmly fastened between the clamp body and the mobile jaw driven by a screw, sometimes after a pre-fastening of the clamp on the conductor). The fastening torque of the clamp on the conductor is ensured by the manual clamping torque of the driving screw.

- Elastic fastening (where the conductor is clamped between the clamp body and the mobile jaw driven by a spring or by elastic systems). In such conditions, the fastening force of the clamp on the conductor is assured by the spring's characteristics.

- Fastening by shape and weight (self-locking). The fastening force of the clamp on the conductor is assured upon the weight of the phase clamp - earthing conductor assembly. In case of phase clamps or earthing clamps with fastening screw, these can be provided with various terminal ends in order to allow the connection of the clamp to other devices or manual handling.

The short-circuiting and earthing cables of the short-circuiting device are manufactured from highly flexible multi-core copper wire, class VI according to SR EN 60228, protected with a transparent insulating layer, directly extruded on the multi-core wire, according to SR EN 61138.

Phase clamps (CLF) and earthing clamps (CLP) are designed and manufactured in a wide range of constructive shapes so that they can be applied on the various shapes of conductors of the low, medium and high voltage installations and to provide the mechanical strength required for the successful handling of an incident determined by the accidental occurrence of voltage in the power installation. Even if it may seem less important, the correct selection of phase and earthing clamps assures improved ergonomic conditions and, at the same time, complete electrical safety.

Phase and earthing clamps are fastened on the installation's conductors or on the earth bars by various methods:

- Screw fastening (where the conductor is firmly fastened between the clamp body and the mobile jaw driven by a screw, sometimes after a pre-fastening of the clamp on the conductor). The fastening torque of the clamp on the conductor is ensured by the manual clamping torque of the driving screw.

- Elastic fastening (where the conductor is clamped between the clamp body and the mobile jaw driven by a spring or by elastic systems). In such conditions, the fastening force of the clamp on the conductor is assured by the spring's characteristics.

- Fastening by shape and weight (self-locking). The fastening force of the clamp on the conductor is assured upon the weight of the phase clamp - earthing conductor assembly. In case of phase clamps or earthing clamps with fastening screw, these can be provided with various terminal ends in order to allow the connection of the clamp to other devices or manual handling.

The screw fastening phase clamp is provided mainly with “RO bayonet” terminal ends, which can be easily connected to and disconnected from the “RO bayonet” coupling systems of insulating sticks.

The earthing clamps - given that they are applied manually on the earthing bar or other similar items - are usually provided with screw with sliding “cross rod”.

The screw of the phase clamp can be provided with following ends: “eyes” (for installation with removable hot-stick), “DIN bayonet” (a system similar to “RO bayonet” but with different dimensions), “hexagon 12” (in order to be operated with a stick provided with a hexagonal coupling system), “insulated handle” (for manual operation).

The screw fastening phase clamp is provided mainly with “RO bayonet” terminal ends, which can be easily connected to and disconnected from the “RO bayonet” coupling systems of insulating sticks.

The earthing clamps - given that they are applied manually on the earthing bar or other similar items - are usually provided with screw with sliding “cross rod”.

The screw of the phase clamp can be provided with following ends: “eyes” (for installation with removable hot-stick), “DIN bayonet” (a system similar to “RO bayonet” but with different dimensions), “hexagon 12” (in order to be operated with a stick provided with a hexagonal coupling system), “insulated handle” (for manual operation).

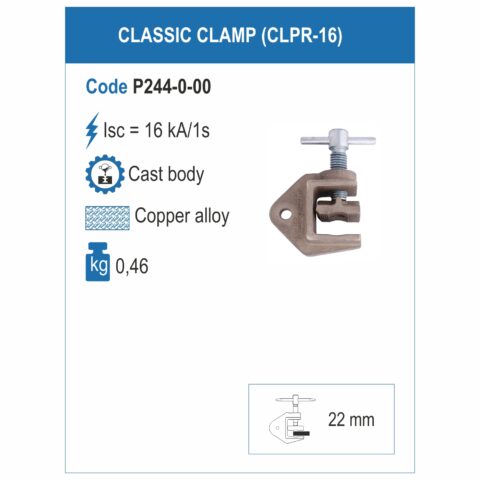

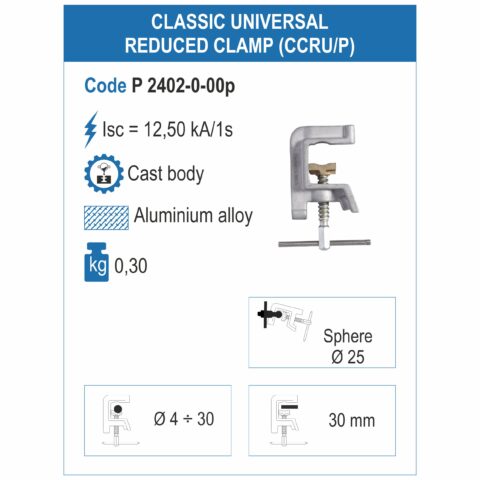

The screw fastening phase clamps can be “classic” or “automatic”.

The "classic" screw clamps have a simple drive screw that provides the movement of the mobile jaw and the fastening of the clamp on the conductor.

The “automatic” screw clamps include a system of levers and springs allows the automated movement of the mobile jaw when the clamp get in contact with the installation's conductor, a movement that provides the pre-fastening of the clamp on the conductor. Subsequently to that stage, the clamp must be firmly tightened on the conductor, acting the screw and locking of the mobile jaw's position.

Elastic fastening or self-locking clamps can be classified in the category of “automatic” clamps, once the clamp is connected/pushed on the conductor, and the conductor remains fastened between the mobile jaw and the body of the clamp.

Depending on the type of the power installation and the shape of conductors / bus-bars, phase clamps are designed - as shape and size - to allow their quick and safe application on:

- Bare conductors of low/medium/high voltage overhead lines,

- Bus-bars or parts with rectangular section (clamps for flat bars),

- Cylindrical bars or parts with round section (clamps for round bars),

- Spherical pieces (Ball studs) of various dimensions,

- Conductors of various forms (universal clamps),

- Terminal parts of various forms / destinations.

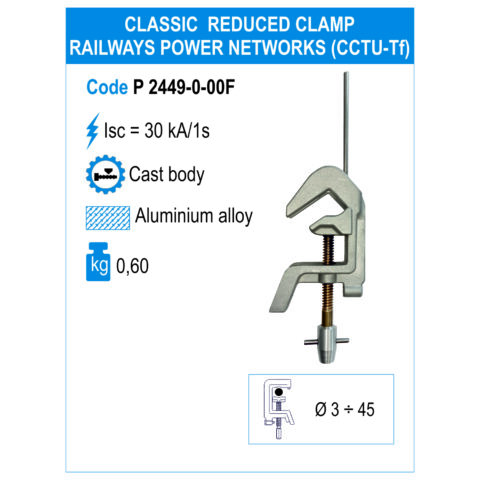

The earthing clamps (CLP) perform the direct connection of short-circuiting devices to natural / artificial earth grounding of the power installation or to the mobile earthing rod. The earthing clamps are manufactured in various shapes and dimensions depending on the value of the rated short-circuit current to be provided by the installation of the short-circuiting device.

The earthing clamps are installed directly by hand on the earthing element. They can be “classic” or they can be provided with “scraping jaw”. By their installation and fastening, earthing clamps with scraping jaw remove the layers of oxides, impurities and protective paint, assuring appropriate contact resistance.

Also, the category of earthing clamps includes the special clamps applicable on railway tracks.

Short-circuiting devices can be packed to store and transport in:

- Waterproof fabric bags of various sizes;

- Plastic cases;

- Painted metal boxes.

The screw fastening phase clamps can be “classic” or “automatic”.

The "classic" screw clamps have a simple drive screw that provides the movement of the mobile jaw and the fastening of the clamp on the conductor.

The “automatic” screw clamps include a system of levers and springs allows the automated movement of the mobile jaw when the clamp get in contact with the installation's conductor, a movement that provides the pre-fastening of the clamp on the conductor. Subsequently to that stage, the clamp must be firmly tightened on the conductor, acting the screw and locking of the mobile jaw's position.

Elastic fastening or self-locking clamps can be classified in the category of “automatic” clamps, once the clamp is connected/pushed on the conductor, and the conductor remains fastened between the mobile jaw and the body of the clamp.

Depending on the type of the power installation and the shape of conductors / bus-bars, phase clamps are designed - as shape and size - to allow their quick and safe application on:

- Bare conductors of low/medium/high voltage overhead lines,

- Bus-bars or parts with rectangular section (clamps for flat bars),

- Cylindrical bars or parts with round section (clamps for round bars),

- Spherical pieces (Ball studs) of various dimensions,

- Conductors of various forms (universal clamps),

- Terminal parts of various forms / destinations.

The earthing clamps (CLP) perform the direct connection of short-circuiting devices to natural / artificial earth grounding of the power installation or to the mobile earthing rod. The earthing clamps are manufactured in various shapes and dimensions depending on the value of the rated short-circuit current to be provided by the installation of the short-circuiting device.

The earthing clamps are installed directly by hand on the earthing element. They can be “classic” or they can be provided with “scraping jaw”. By their installation and fastening, earthing clamps with scraping jaw remove the layers of oxides, impurities and protective paint, assuring appropriate contact resistance.

Also, the category of earthing clamps includes the special clamps applicable on railway tracks.

Short-circuiting devices can be packed to store and transport in:

- Waterproof fabric bags of various sizes;

- Plastic cases;

- Painted metal boxes.

Accessories for mobile earthing devices

Phase clamps / earthing clamps

Mobile earthing and short-circuiting devices (currently referred to as “short-circuiting devices”) represent safety equipment used for temporary earthing and short-circuiting of conductors of a power installation.

The use of short-circuiting devices represents the main preventive protection measure for professional operators against an accidental commissioning or possible voltage return during repair operations in the working area.

The installation of short-circuiting devices must be performed by two professional operators, in the following sequence of operations:

- Earthing of the short-circuiting device by the fastening of the earthing clamp or of the crimped lug of the earthing cable to the artificial / natural earth grounding of the power installation or to the mobile earthing rod, previously buried;

- Checking the absence of voltage on conductors to be earthed / short-circuited, using a voltage detector;

- Installation of the phase clamps (CLF) of the short-circuiting device, which allow a good connection between the phase conductor and the earth.

Depending on the type of the short-circuiting device and the voltage of the power installation where the short-circuiting device is applied, the installation of the phase clamps on the conductors must be performed using insulating sticks / poles / handles specially designed for this operation.

Short-circuiting devices are made in accordance with the provisions of SR EN 61230 standard, in various constructive configurations: single-phase, three-phase or poly-phase and can be installed both in indoor and outdoor power installations. Short-circuiting and earthing cables will be connected in various configurations, according to the needs.

Mobile earthing and short-circuiting devices (currently referred to as “short-circuiting devices”) represent safety equipment used for temporary earthing and short-circuiting of conductors of a power installation.

The use of short-circuiting devices represents the main preventive protection measure for professional operators against an accidental commissioning or possible voltage return during repair operations in the working area.

The installation of short-circuiting devices must be performed by two professional operators, in the following sequence of operations:

- Earthing of the short-circuiting device by the fastening of the earthing clamp or of the crimped lug of the earthing cable to the artificial / natural earth grounding of the power installation or to the mobile earthing rod, previously buried;

- Checking the absence of voltage on conductors to be earthed / short-circuited, using a voltage detector;

- Installation of the phase clamps (CLF) of the short-circuiting device, which allow a good connection between the phase conductor and the earth.

Depending on the type of the short-circuiting device and the voltage of the power installation where the short-circuiting device is applied, the installation of the phase clamps on the conductors must be performed using insulating sticks / poles / handles specially designed for this operation.

Short-circuiting devices are made in accordance with the provisions of SR EN 61230 standard, in various constructive configurations: single-phase, three-phase or poly-phase and can be installed both in indoor and outdoor power installations. Short-circuiting and earthing cables will be connected in various configurations, according to the needs.

The central junction of the three-phase short-circuiting devices can be constructed in two design variants: with a central connector insulated with heat shrink tube or with a connecting block covered with insulating housing, that allows inspection of the junction.

The central junction of the three-phase short-circuiting devices can be constructed in two design variants: with a central connector insulated with heat shrink tube or with a connecting block covered with insulating housing, that allows inspection of the junction.

The short-circuiting and earthing cables of the short-circuiting device are manufactured from highly flexible multi-core copper wire, class VI according to SR EN 60228, protected with a transparent insulating layer, directly extruded on the multi-core wire, according to SR EN 61138.

Phase clamps (CLF) and earthing clamps (CLP) are designed and manufactured in a wide range of constructive shapes so that they can be applied on the various shapes of conductors of the low, medium and high voltage installations and to provide the mechanical strength required for the successful handling of an incident determined by the accidental occurrence of voltage in the power installation. Even if it may seem less important, the correct selection of phase and earthing clamps assures improved ergonomic conditions and, at the same time, complete electrical safety.

Phase and earthing clamps are fastened on the installation's conductors or on the earth bars by various methods:

- Screw fastening (where the conductor is firmly fastened between the clamp body and the mobile jaw driven by a screw, sometimes after a pre-fastening of the clamp on the conductor). The fastening torque of the clamp on the conductor is ensured by the manual clamping torque of the driving screw.

- Elastic fastening (where the conductor is clamped between the clamp body and the mobile jaw driven by a spring or by elastic systems). In such conditions, the fastening force of the clamp on the conductor is assured by the spring's characteristics.

- Fastening by shape and weight (self-locking). The fastening force of the clamp on the conductor is assured upon the weight of the phase clamp - earthing conductor assembly. In case of phase clamps or earthing clamps with fastening screw, these can be provided with various terminal ends in order to allow the connection of the clamp to other devices or manual handling.

The short-circuiting and earthing cables of the short-circuiting device are manufactured from highly flexible multi-core copper wire, class VI according to SR EN 60228, protected with a transparent insulating layer, directly extruded on the multi-core wire, according to SR EN 61138.

Phase clamps (CLF) and earthing clamps (CLP) are designed and manufactured in a wide range of constructive shapes so that they can be applied on the various shapes of conductors of the low, medium and high voltage installations and to provide the mechanical strength required for the successful handling of an incident determined by the accidental occurrence of voltage in the power installation. Even if it may seem less important, the correct selection of phase and earthing clamps assures improved ergonomic conditions and, at the same time, complete electrical safety.

Phase and earthing clamps are fastened on the installation's conductors or on the earth bars by various methods:

- Screw fastening (where the conductor is firmly fastened between the clamp body and the mobile jaw driven by a screw, sometimes after a pre-fastening of the clamp on the conductor). The fastening torque of the clamp on the conductor is ensured by the manual clamping torque of the driving screw.

- Elastic fastening (where the conductor is clamped between the clamp body and the mobile jaw driven by a spring or by elastic systems). In such conditions, the fastening force of the clamp on the conductor is assured by the spring's characteristics.

- Fastening by shape and weight (self-locking). The fastening force of the clamp on the conductor is assured upon the weight of the phase clamp - earthing conductor assembly. In case of phase clamps or earthing clamps with fastening screw, these can be provided with various terminal ends in order to allow the connection of the clamp to other devices or manual handling.

The screw fastening phase clamp is provided mainly with “RO bayonet” terminal ends, which can be easily connected to and disconnected from the “RO bayonet” coupling systems of insulating sticks.

The earthing clamps - given that they are applied manually on the earthing bar or other similar items - are usually provided with screw with sliding “cross rod”.

The screw of the phase clamp can be provided with following ends: “eyes” (for installation with removable hot-stick), “DIN bayonet” (a system similar to “RO bayonet” but with different dimensions), “hexagon 12” (in order to be operated with a stick provided with a hexagonal coupling system), “insulated handle” (for manual operation).

The screw fastening phase clamp is provided mainly with “RO bayonet” terminal ends, which can be easily connected to and disconnected from the “RO bayonet” coupling systems of insulating sticks.

The earthing clamps - given that they are applied manually on the earthing bar or other similar items - are usually provided with screw with sliding “cross rod”.

The screw of the phase clamp can be provided with following ends: “eyes” (for installation with removable hot-stick), “DIN bayonet” (a system similar to “RO bayonet” but with different dimensions), “hexagon 12” (in order to be operated with a stick provided with a hexagonal coupling system), “insulated handle” (for manual operation).

The screw fastening phase clamps can be “classic” or “automatic”.

The "classic" screw clamps have a simple drive screw that provides the movement of the mobile jaw and the fastening of the clamp on the conductor.

The “automatic” screw clamps include a system of levers and springs allows the automated movement of the mobile jaw when the clamp get in contact with the installation's conductor, a movement that provides the pre-fastening of the clamp on the conductor. Subsequently to that stage, the clamp must be firmly tightened on the conductor, acting the screw and locking of the mobile jaw's position.

Elastic fastening or self-locking clamps can be classified in the category of “automatic” clamps, once the clamp is connected/pushed on the conductor, and the conductor remains fastened between the mobile jaw and the body of the clamp.

Depending on the type of the power installation and the shape of conductors / bus-bars, phase clamps are designed - as shape and size - to allow their quick and safe application on:

- Bare conductors of low/medium/high voltage overhead lines,

- Bus-bars or parts with rectangular section (clamps for flat bars),

- Cylindrical bars or parts with round section (clamps for round bars),

- Spherical pieces (Ball studs) of various dimensions,

- Conductors of various forms (universal clamps),

- Terminal parts of various forms / destinations.

The earthing clamps (CLP) perform the direct connection of short-circuiting devices to natural / artificial earth grounding of the power installation or to the mobile earthing rod. The earthing clamps are manufactured in various shapes and dimensions depending on the value of the rated short-circuit current to be provided by the installation of the short-circuiting device.

The earthing clamps are installed directly by hand on the earthing element. They can be “classic” or they can be provided with “scraping jaw”. By their installation and fastening, earthing clamps with scraping jaw remove the layers of oxides, impurities and protective paint, assuring appropriate contact resistance.

Also, the category of earthing clamps includes the special clamps applicable on railway tracks.

Short-circuiting devices can be packed to store and transport in:

- Waterproof fabric bags of various sizes;

- Plastic cases;

- Painted metal boxes.

The screw fastening phase clamps can be “classic” or “automatic”.

The "classic" screw clamps have a simple drive screw that provides the movement of the mobile jaw and the fastening of the clamp on the conductor.

The “automatic” screw clamps include a system of levers and springs allows the automated movement of the mobile jaw when the clamp get in contact with the installation's conductor, a movement that provides the pre-fastening of the clamp on the conductor. Subsequently to that stage, the clamp must be firmly tightened on the conductor, acting the screw and locking of the mobile jaw's position.

Elastic fastening or self-locking clamps can be classified in the category of “automatic” clamps, once the clamp is connected/pushed on the conductor, and the conductor remains fastened between the mobile jaw and the body of the clamp.

Depending on the type of the power installation and the shape of conductors / bus-bars, phase clamps are designed - as shape and size - to allow their quick and safe application on:

- Bare conductors of low/medium/high voltage overhead lines,

- Bus-bars or parts with rectangular section (clamps for flat bars),

- Cylindrical bars or parts with round section (clamps for round bars),

- Spherical pieces (Ball studs) of various dimensions,

- Conductors of various forms (universal clamps),

- Terminal parts of various forms / destinations.

The earthing clamps (CLP) perform the direct connection of short-circuiting devices to natural / artificial earth grounding of the power installation or to the mobile earthing rod. The earthing clamps are manufactured in various shapes and dimensions depending on the value of the rated short-circuit current to be provided by the installation of the short-circuiting device.

The earthing clamps are installed directly by hand on the earthing element. They can be “classic” or they can be provided with “scraping jaw”. By their installation and fastening, earthing clamps with scraping jaw remove the layers of oxides, impurities and protective paint, assuring appropriate contact resistance.

Also, the category of earthing clamps includes the special clamps applicable on railway tracks.

Short-circuiting devices can be packed to store and transport in:

- Waterproof fabric bags of various sizes;

- Plastic cases;

- Painted metal boxes.