Mounting device of sleeves in concrete plates

Mounting device of sleeves in concrete plates

The mounting devices of sleeves in concrete plates are manufactured in various types, depending on the thickness of the concrete plate that will be made.

These can be used for concrete plates with thickness between 50 and 200 mm.

General mounting instructions of the sleeves of RAP nozzles in the concrete plates

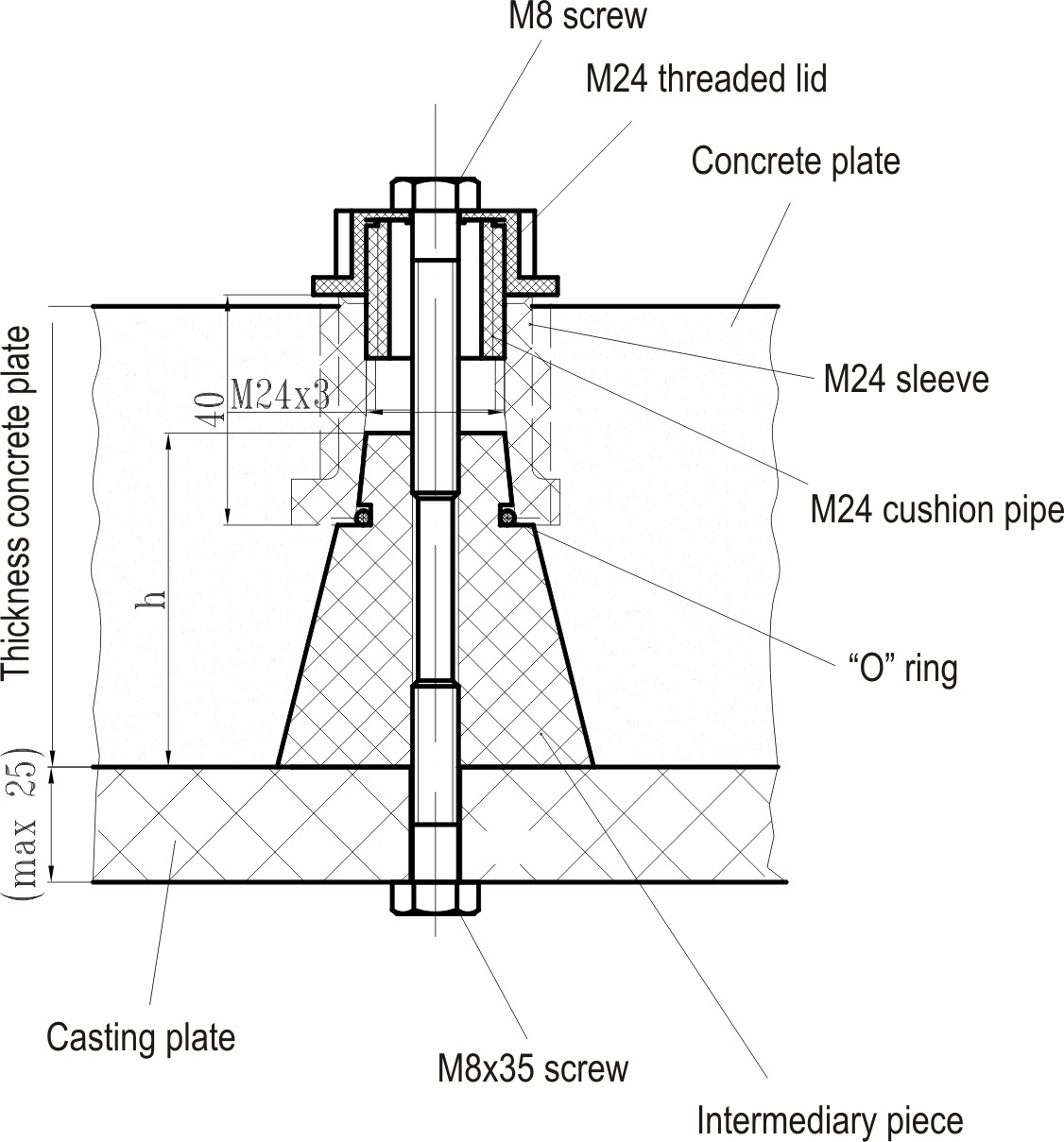

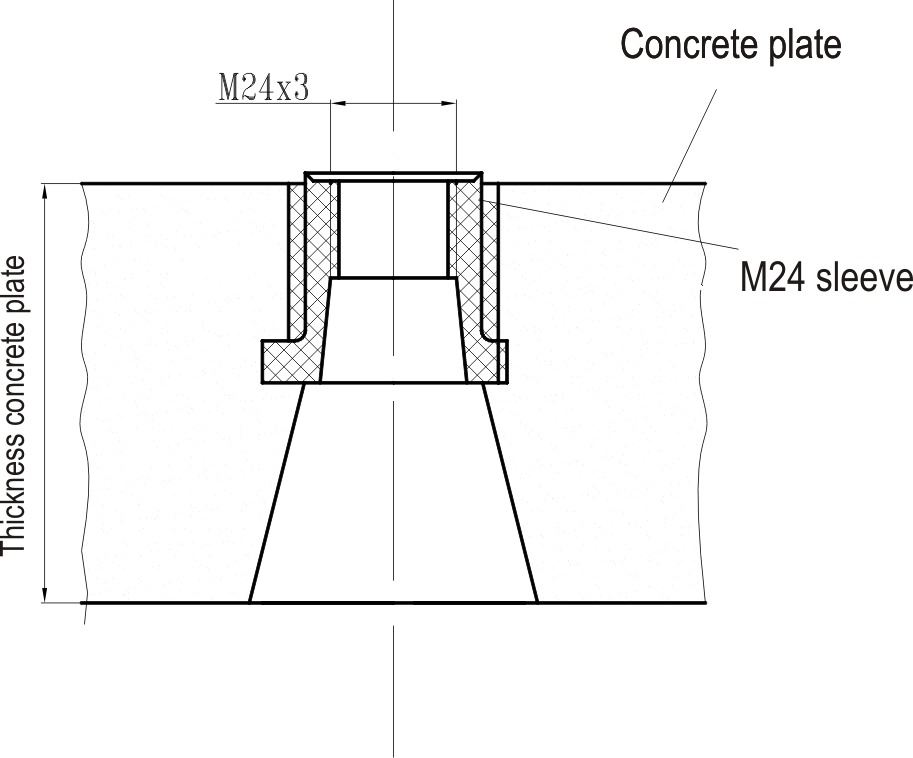

These below instructions present the mounting of the M24 threaded sleeves in the concrete plates for the free level filters. This concrete plate will be precasted in factory before putting it on site.

Before mounting, it must be verified the structure and integrity of the mounting device.

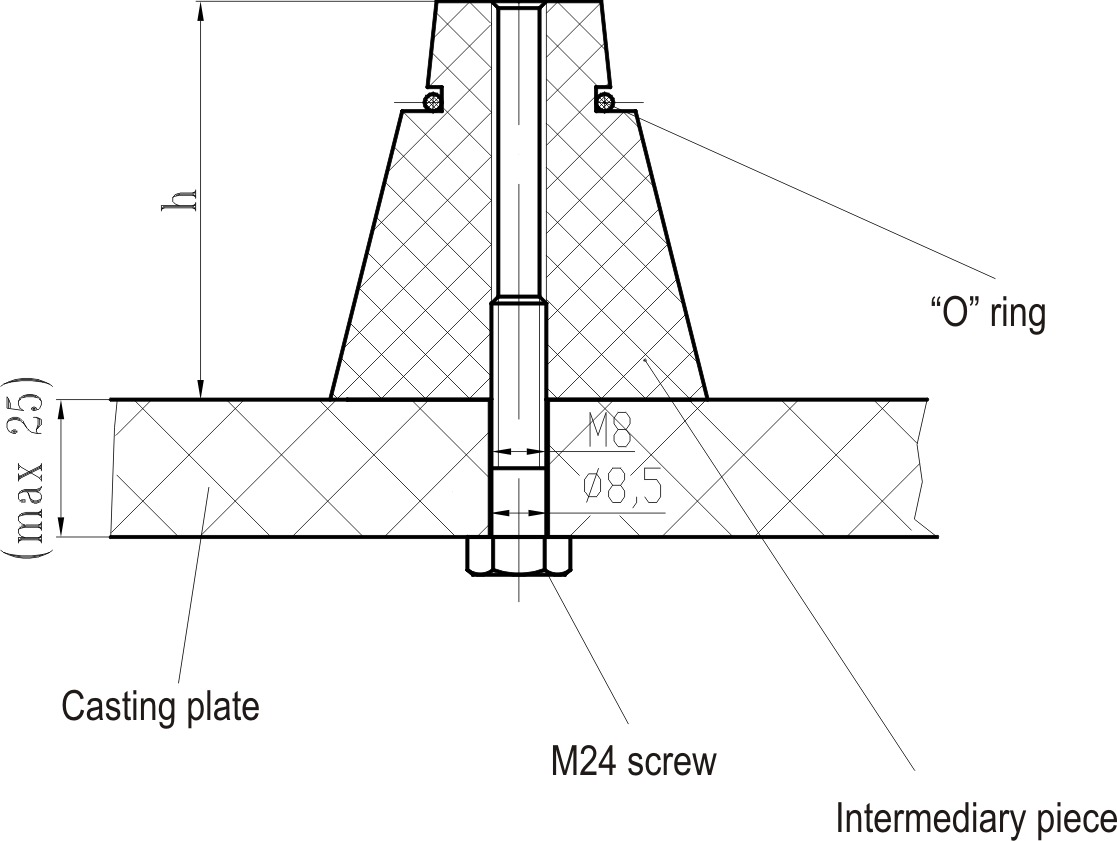

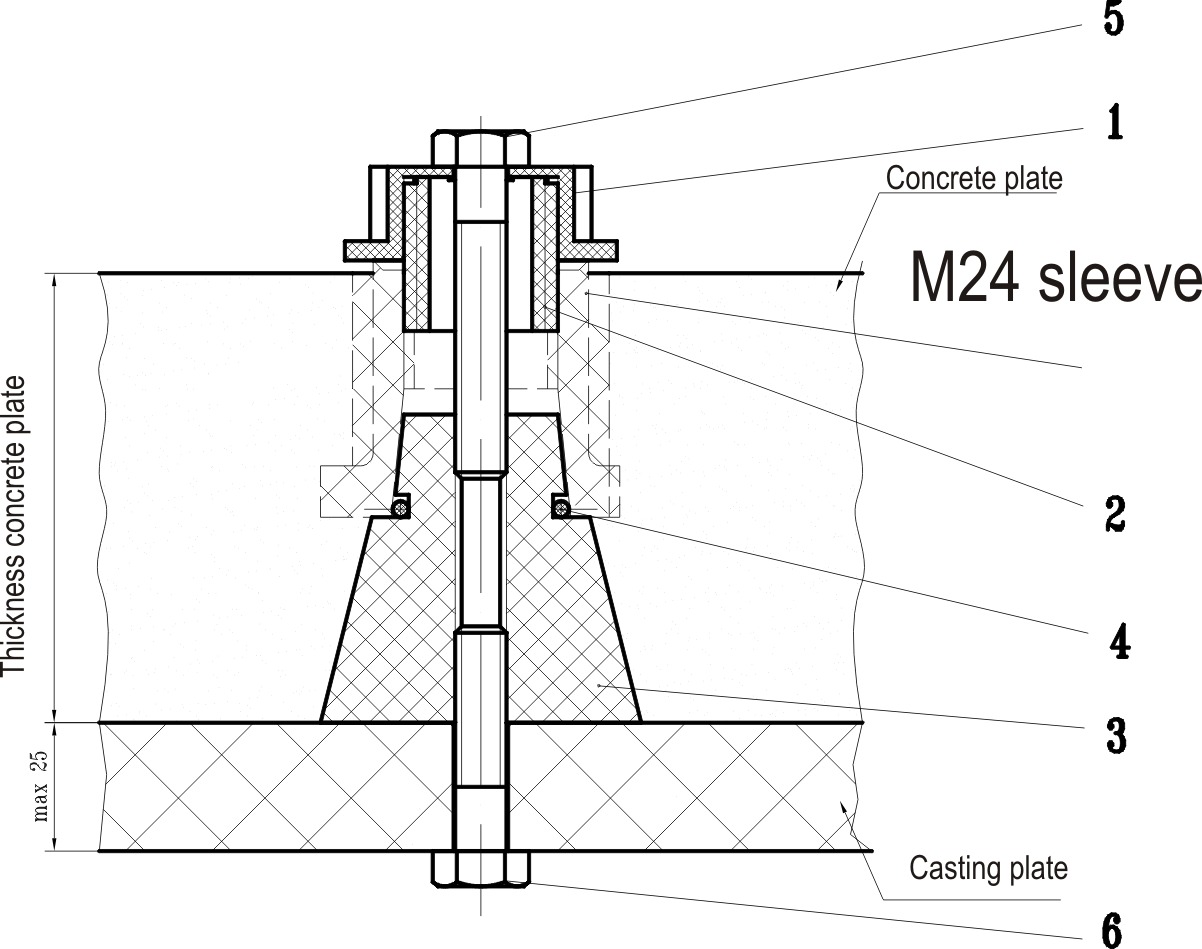

1. Verify on the casing plate the distance between the Ø 8,5 holes. According the figure, there are introduced in these holes, on the inferior part, the M8x35 screws; on the other part it is screwed the intermediary piece. The tightening is made with a maximum tightening torque of 5 Nm.

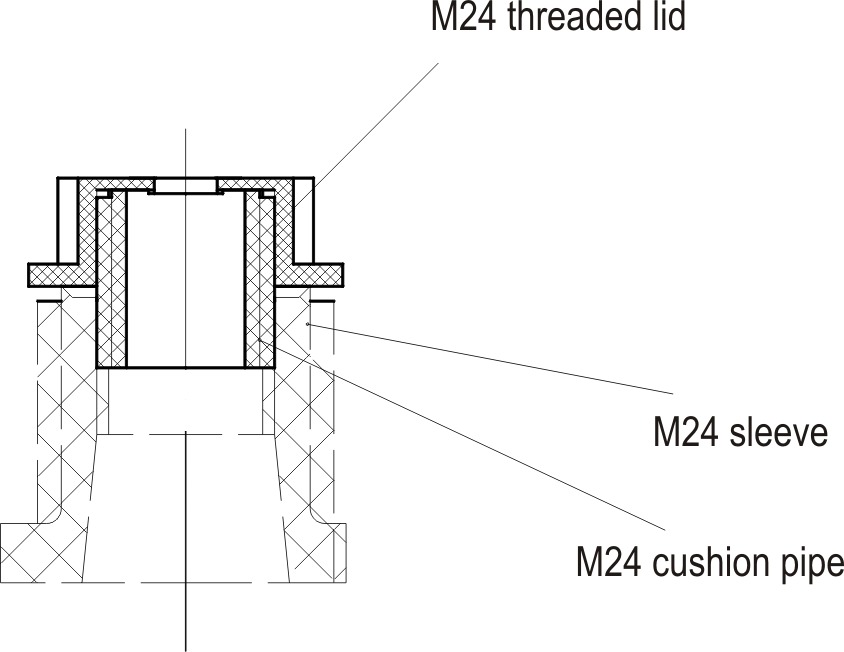

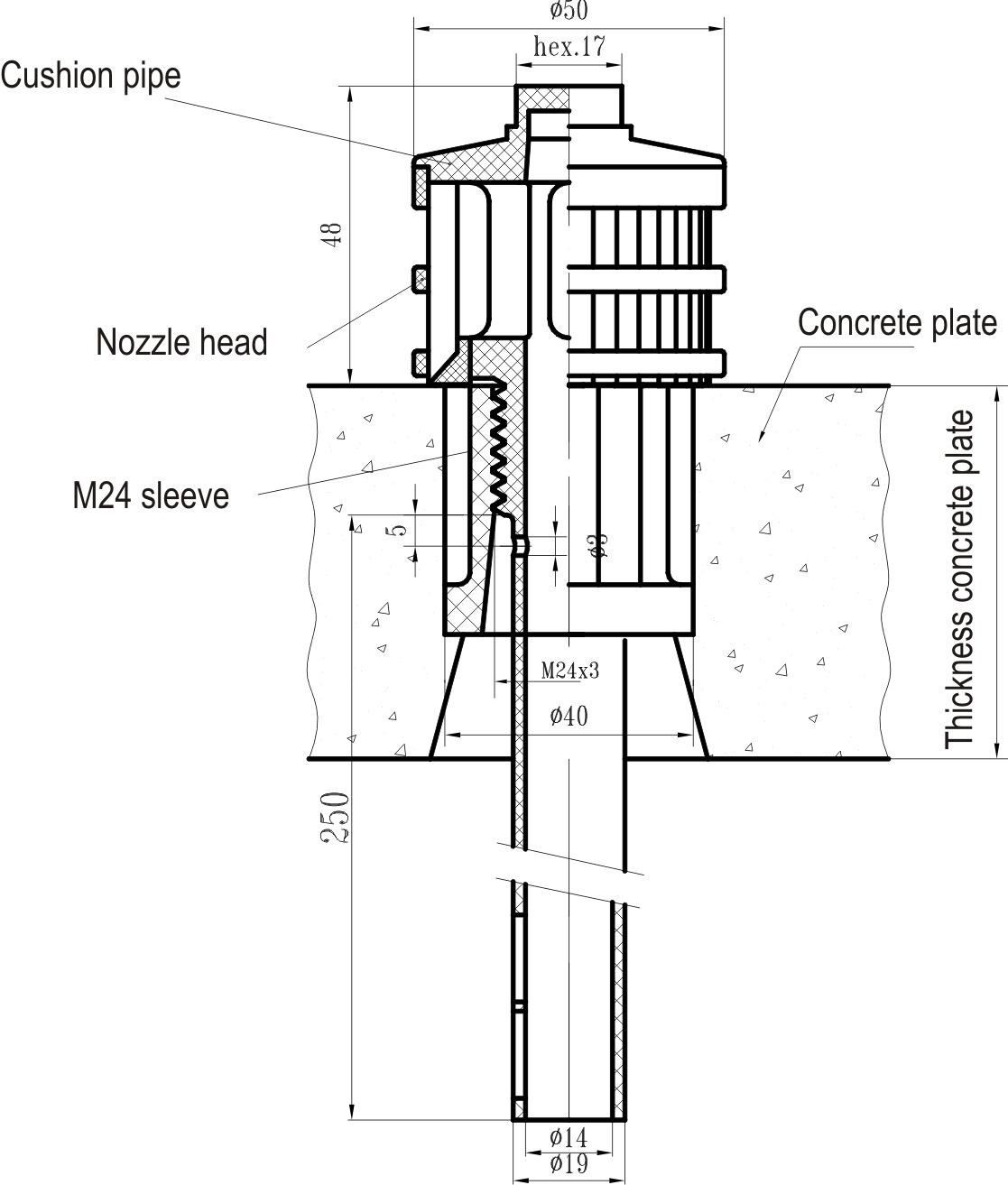

2. Separately, it is mounted (as a subassembly) the M24 threaded lid and the M24 cushion pipe by manual screwing; this subassembly is mounted in the threaded sleeve M24. The tightening of the components is made manually.

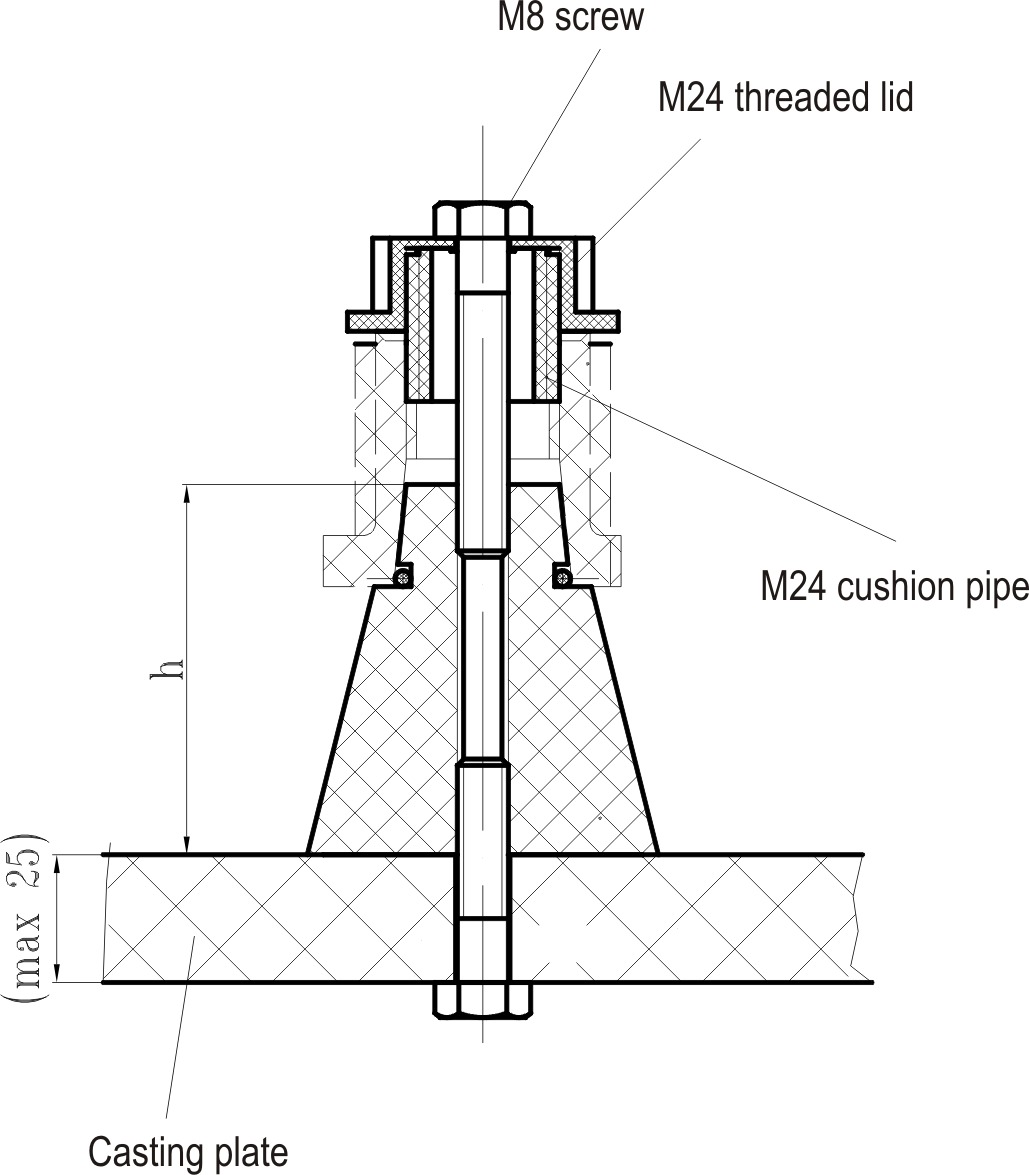

3. It is mounted the subassembly made at point 2 in the intermediary piece and it is tightened the M8 screw. The tightening is made with a tightening torque of maximum 5 Nm.

4. After mounting all the devices positioned according the drawing, it is poured concrete in order to obtain the desired plate thickness. In order to level the concrete plate, it is recommended to be used a vibrating plate on which it is placed the casing plate.

5. After the concrete has hardened, it is unscrewed the M8 screw, the M24 threaded lid and the M24 cushion pipe; there are unscrewed the M8x35 screws and the casing plate is removed. The M8x35 screws are afterwards screwed in the intermediary pieces in order to allow their pulling out from the concrete plate.

6. The concrete plate is put and fixed on site. It is screwed the assembled cushion pipe with the nozzle head in the M24 sleeve incorporated in the concrete plate.

Structure:

1. Threaded lid;

2. Cushion pipe M24;

3. Intermediary piece;

4. Ring “O” type;

5, 6. Hexagonal screw (2 pieces).

-80x80.jpg)