Cooling tower MCE type

Cooling tower MCE type

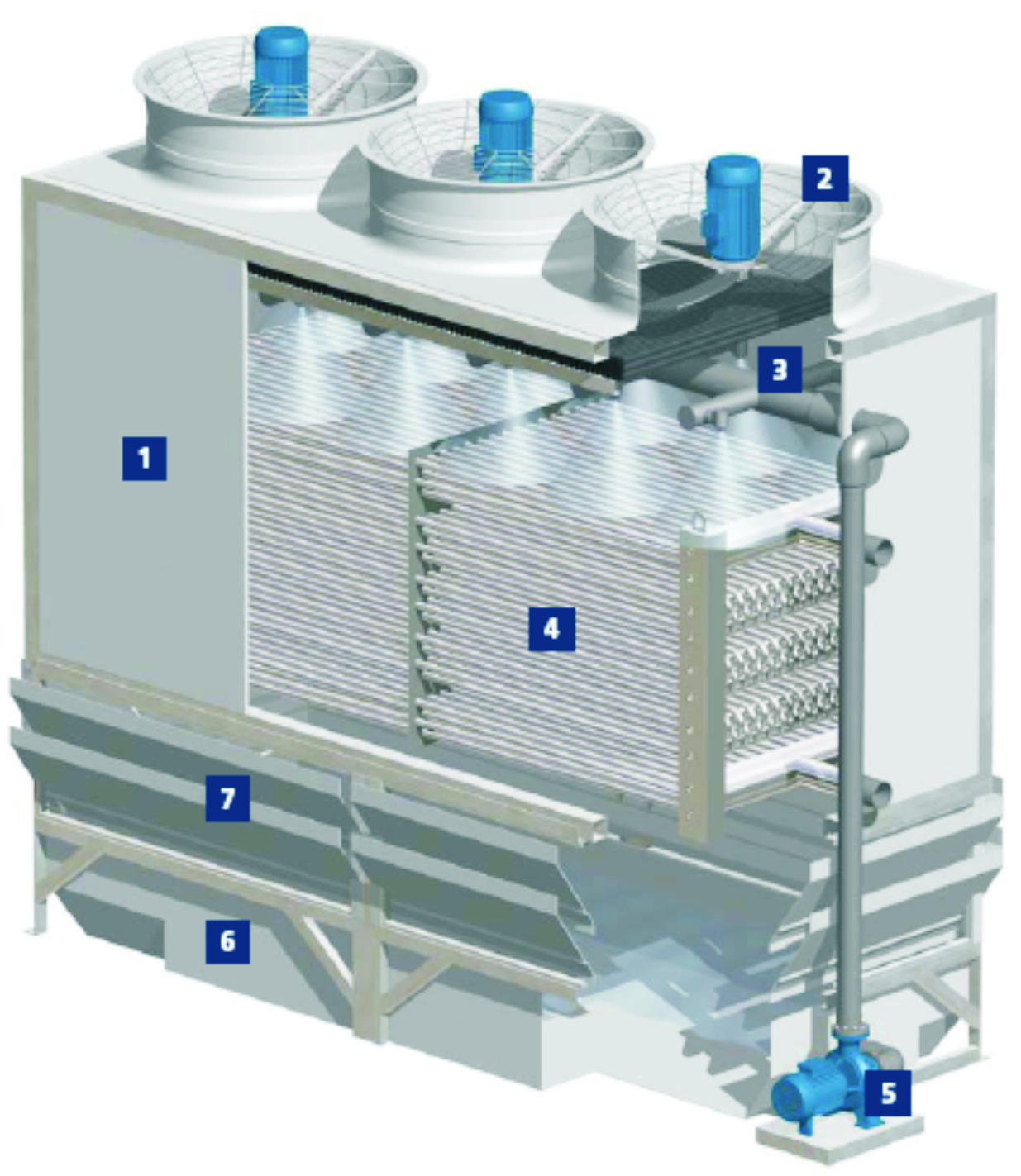

The MCE cooling towers are similar with the MCC cooling tower, the main difference is that the substance circulating throught the heat exchange coil is gas.

Mixed structure casing

Construction materials:

• steel support structure, hot-dip galvanized after fabrication, fibreglass sandwich panelling of 22 mm thickness, with three side-walls completely removable as standard supply

Characteristics:

• optimum mechanical strength

• good sound absorbtion effect

• non-corroding

• ease of internal inspection.

Multi-blade axial fan

Construction materials:

• hot-dip galvanized steel (electric motor support), fibreglass reinforced plastic (fan blades), stainless steel (screen grille)

Characteristics:

• high performance, low electrical power input, fan directly driven by the electric motor

• constant safety, unaltered over time thanks to the screen grille.

Heat exchange coil

Construction materials:

• hot-dip galvanized steel (on request, stainless steel for the MCC series)

Characteristics:

• high heat exchange surface

• more convenient maintenance (thanks to the openable side-walls)

In the case of the MCE series the heat exchange coil is manufactured in compliance with the PED directive 97/23/EC

Centrifugal water recirculating pump and spray water circuit piping

Basin (complete with electric resistance anti-freezeheater and related thermostat)

Construction materials:

• orthophthalic polyester resin, reinforced with several layers of glassfibre matting

Characteristics:

• external surface protection with a gel-coat resistant to UV radiation, hot and cold water, abrasion caused by weathering and by chemicals

• basin with internal waterproofing by means of an impermeable, water repellent, paraffin-containing orthophthalic gel-coat

• possibility of sloping water collecting basins for complete emptying of water

• light-weight

• non-corroding

Dimensional elements:

A – Total height of tower

B, C – Length / Width of the cooling tower (horizontally)

MCE Cooling tower

|

Type |

A |

B |

C |

Fan |

Pump |

Weight [kg] Empty In operation | |

|

A1/A3 |

1870 |

1030 |

3160 |

2 x 0,75 |

1,1 |

1200 |

2200 |

|

B1/B3 |

2770 |

1030 |

3160 |

3 x 0,75 |

1,1 |

1645 |

3100 |

|

D1/D3 |

2850 |

1235 |

3250 |

2 x 1,5 |

1,1 |

1865 |

3630 |

|

E1/E3 |

3670 |

1235 |

3250 |

3 x 1,5 |

1,5 |

2200 |

4500 |

|

H1/H3 |

3670 |

1505 |

3460 |

3 x 1,5 |

2,2 |

2710 |

5330 |

|

I1/I3 |

4570 |

1505 |

3610 |

3 x 2,2 |

3 |

3260 |

6550 |

|

M1/M3 |

2850 |

2340 |

3650 |

1 x 5,5 |

3 |

3510 |

7100 |

|

N1/N3 |

3690 |

2340 |

3650 |

1 x 7,5 |

3 |

4135 |

8685 |

|

P1/P3 |

4570 |

2340 |

3800 |

2 x 5,5 |

4 |

5215 |

10800 |

|

Q1/Q3 |

5500 |

2340 |

3800 |

2 x 5,5 |

4 |

6215 |

12500 |

|

R1/R3 |

4520 |

2960 |

4235 |

2 x 5,5 |

4 |

6500 |

13000 |

|

S1/S3 |

5470 |

2960 |

4235 |

2 x 5,5 |

5,5 |

7500 |

15500 |

1. Body

2. Axial fan

3. Cooling water distribution system

4. Heat exchange coil (the cooled fluid circulates through the inside)

5. Pump

6. Basin (optional)

7. Screen grille