Cooling tower MCC type

Cooling tower MCC type

Mixed structure casing

Construction materials:

• steel support structure, hot-dip galvanized after fabrication, fibreglass sandwich panelling of 22 mm thickness, with three side-walls completely removable as standard supply

Characteristics:

• optimum mechanical strength

• good sound absorbtion effect

• non-corroding

• ease of internal inspection.

Multi-blade axial fan

Construction materials:

• hot-dip galvanized steel (electric motor support), fibreglass reinforced plastic (fan blades), stainless steel (screen grille)

Characteristics:

• high performance, low electrical power input, fan directly driven by the electric motor

• constant safety, unaltered over time thanks to the screen grille

Heat exchange coil

Construction materials:

• hot-dip galvanized steel (on request, stainless steel for the MCC series)

Characteristics:

• high heat exchange surface

• more convenient maintenance (thanks to the openable side-walls)

Centrifugal water recirculating pump and spray water circuit piping

Basin (complete with electric resistance anti-freezeheater and related thermostat)

Construction materials:

• orthophthalic polyester resin, reinforced with several layers of glassfibre matting

Characteristics:

• external surface protection with a gel-coat resistant to UV radiation, hot and cold water, abrasion caused by weathering and by chemicals

• basin with internal waterproofing by means of an impermeable, water repellent, paraffin-containing orthophthalic gel-coat

• possibility of sloping water collecting basins for complete emptying of water

• light-weight

• non-corroding

Dimensional elements:

A – Total height of tower

B, C – Length / Width of the cooling tower (horizontally)

MCC Cooling tower

|

Type |

A |

B |

C |

Axial fan |

Pump |

Weight [kg] Empty In operation |

|

|

A1/A3 |

1870 |

1030 |

3160 |

2 x 0,75 |

1,1 |

1200 |

2200 |

|

B1/B3 |

2770 |

1030 |

3160 |

3 x 0,75 |

1,1 |

1645 |

3100 |

|

D1/D3 |

2850 |

1235 |

3250 |

2 x 1,5 |

1,1 |

1865 |

3630 |

|

E1/E3 |

3670 |

1235 |

3250 |

3 x 1,5 |

1,5 |

2200 |

4500 |

|

H1/H3 |

3670 |

1505 |

3460 |

3 x 1,5 |

2,2 |

2710 |

5330 |

|

I1/I3 |

4570 |

1505 |

3610 |

3 x 2,2 |

3 |

3260 |

6550 |

|

M1/M3 |

2850 |

2340 |

3650 |

1 x 5,5 |

3 |

3510 |

7100 |

|

N1/N3 |

3690 |

2340 |

3650 |

1 x 7,5 |

3 |

4135 |

8685 |

|

P1/P3 |

4570 |

2340 |

3800 |

2 x 5,5 |

4 |

5215 |

10800 |

|

Q1/Q3 |

5500 |

2340 |

3800 |

2 x 5,5 |

4 |

6215 |

12500 |

|

R1/R3 |

4520 |

2960 |

4235 |

2 x 5,5 |

4 |

6500 |

13000 |

|

S1/S3 |

5470 |

2960 |

4235 |

2 x 5,5 |

5,5 |

7500 |

15500 |

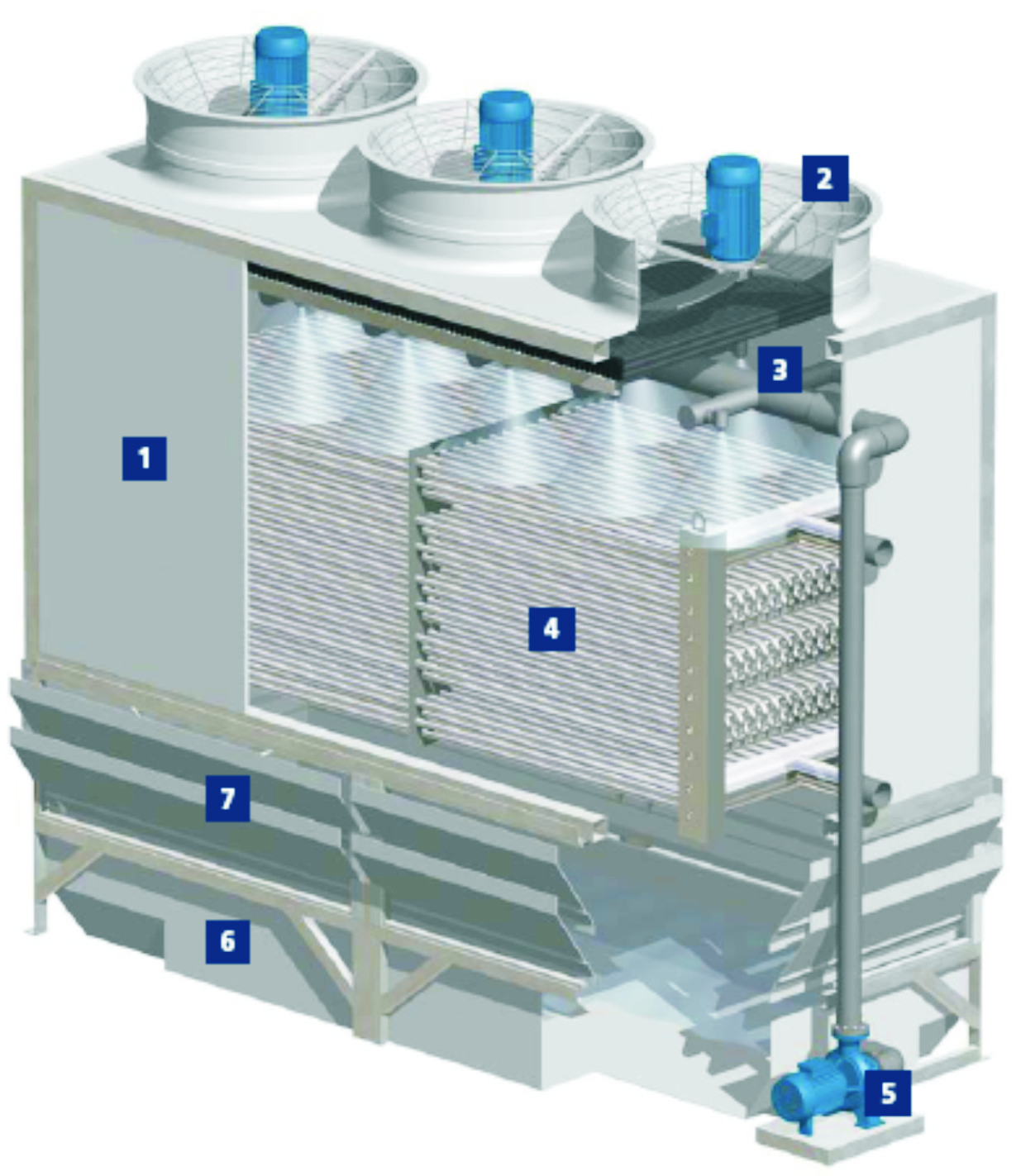

1. Body

2. Axial fan

3. Cooling water distribution system

4. Heat exchange coil (the cooled fluid circulates through the inside)

5. Pump

6. Basin (optional)

7. Shutters