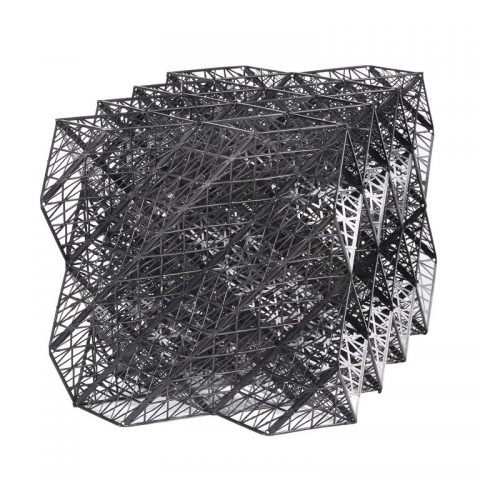

The general technical performances of the cooling towers are mainly influenced by the functional characteristics of the cooling tower fill used in the cooling systems. Romind T&G can deliver both film fill (R27) and splash fill (R80).

The main qualities of the fill are:

- very good thermal performances;

- very good report between acquisition cost and effectiveness;

- resistance to physical, chemical, water and air biological factors;

- very long life cycle;

- fire resistant (flame or fireproof);

- light weighted per volume unit;

- small transport volume (if the components are unassembled);

- high productivity at site installation;

- does not pollute the environment.

For each application, Romind T&G establishes through technical - ergonomically calculus the necessary fill volume and the optimal configuration, depending on the type and dimensions of the cooling tower, the functional requirements of the beneficiary and the environment parameters.

The cooling tower fill can be delivered as follows:

a) unassembled individual elements, method that allows a small transport volume, the assembly of the elements being done on site by the beneficiary, with connection ties (R 80 fill) or by adhesive gluing (R 27 fill),

b) Assembled in packages (modules), directly mounted in the cooling tower on an adequate sustaining system.

The general technical performances of the cooling towers are mainly influenced by the functional characteristics of the cooling tower fill used in the cooling systems. Romind T&G can deliver both film fill (R27) and splash fill (R80).

The main qualities of the fill are:

- very good thermal performances;

- very good report between acquisition cost and effectiveness;

- resistance to physical, chemical, water and air biological factors;

- very long life cycle;

- fire resistant (flame or fireproof);

- light weighted per volume unit;

- small transport volume (if the components are unassembled);

- high productivity at site installation;

- does not pollute the environment.

For each application, Romind T&G establishes through technical - ergonomically calculus the necessary fill volume and the optimal configuration, depending on the type and dimensions of the cooling tower, the functional requirements of the beneficiary and the environment parameters.

The cooling tower fill can be delivered as follows:

a) unassembled individual elements, method that allows a small transport volume, the assembly of the elements being done on site by the beneficiary, with connection ties (R 80 fill) or by adhesive gluing (R 27 fill),

b) Assembled in packages (modules), directly mounted in the cooling tower on an adequate sustaining system.